Mochini o Tummeng oa Pampiri ea Litaba o nang le Bokhoni bo Fapaneng

Paramethara e ka Sehloohong ea Tekheniki

| 1. Lintho tse tala | Letlapa la patsi la mechini (kapa letlapa le leng la lik'hemik'hale), Koranta ea litšila |

| 2. Pampiri ea tlhahiso | Pampiri e hatisitsoeng ea litaba |

| 3. Boima ba pampiri ea tlhahiso | 42-55 g/m2 |

| 4. Bophara ba pampiri ea tlhahiso | 1800-4800mm |

| 5. Bophara ba terata | 2300-5400 mm |

| 6. Bophara ba molomo oa lebokose la hlooho | 2150-5250mm |

| 7. Bokgoni | Lithane tse 10-150 ka Letsatsi |

| 8. Lebelo la ho sebetsa | 80-500m/motsotso |

| 9. Lebelo la moralo | 100-550m/motsotso |

| 10. Tekanyo ea seporo | 2800-6000 mm |

| 11. Tsela ea ho khanna | Lebelo le fetolehang la phetoho ea maqhubu a hona joale, drive ea likarolo |

| 12. Sebopeho | Mochini o le mong, o ka letsohong le letšehali kapa le letona |

Boemo ba Tekheniki ba Ts'ebetso

Koranta ea lehong la mechini kapa ea litšila → Sistimi ea ho lokisa setoko → Karolo ea terata → Karolo ea khatiso → Sehlopha sa ho omisa → Karolo ea ho letsa → Sekenara sa pampiri → Karolo e thekeselang → Karolo ea ho seha le ho kgutlisa morao

Boemo ba Tekheniki ba Ts'ebetso

Litlhoko tsa Metsi, motlakase, mouoane, moea o hatelletsoeng le setlolo:

1. Metsi a hloekileng le boemo ba tšebeliso ea metsi bo sebelisitsoeng hape:

Boemo ba metsi a hloekileng: bo hloekileng, ha bo na 'mala, lehlabathe le tlaase

Khatello ea metsi a hloekileng e sebelisoang bakeng sa boiler le sistimi ea ho hloekisa: 3Mpa, 2Mpa, 0.4Mpa (mefuta e 3) Boleng ba PH: 6~8

Boemo ba ho sebelisa metsi hape:

COD≦600 BOD≦240 SS≦80 ℃20-38 PH6-8

2. Paramethara ea phepelo ea motlakase

Motlakase: 380/220V ± 10%

Motlakase oa tsamaiso ea ho laola: 220/24V

Maqhubu: 50HZ ± 2

3. Ho sebetsa ka mouoane khatello bakeng sa dryer ≦0.5Mpa

4. Moea o hatelletsoeng

● Khatello ea mohloli oa moea: 0.6 ~0.7Mpa

● Khatello ea ho sebetsa: ≤0.5Mpa

● Litlhoko: ho sefa, ho tlosa mafura, ho tlosa metsi, ho omisa

Mocheso oa phepelo ea moea: ≤35℃

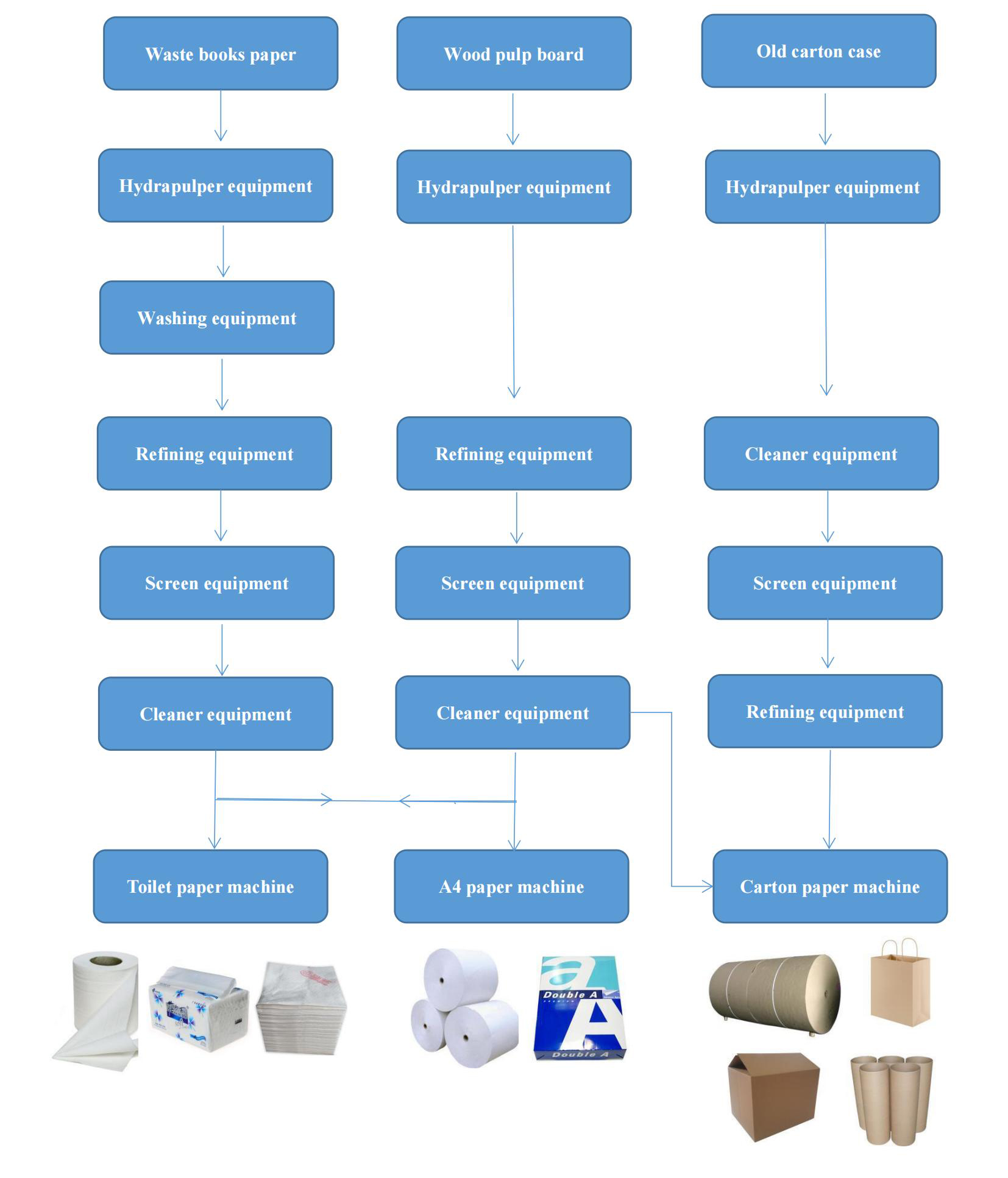

Chate ea ho etsa pampiri (pampiri ea litšila kapa boto ea lepolanka e le thepa e tala)