Mochini oa Pampiri oa Li-tissue oa Crescent oa Lebelo le Phahameng

Paramethara e ka Sehloohong ea Tekheniki

| 1. Lintho tse tala | Pulp ea Virgin e soeufalitsoeng (pulp ea lehong, pulp ea lehlaka, pulp ea joang); Ho Seha ho Tšoeu hape |

| 2. Pampiri ea tlhahiso | Moqolo o moholo oa Jumbo bakeng sa pampiri ea lisele tsa sefahleho le pampiri ea ntloana |

| 3. Boima ba pampiri e hlahisoang | 12-25g/m2 |

| 4. Bokgoni | Lithane tse 25-50 ka letsatsi |

| 5. Bophara ba pampiri ea net | 2850-3600mm |

| 6. Bophara ba terata | 3300-4000mm |

| 7. Lebelo la ho sebetsa | 500-1000m/motsotso |

| 8. Lebelo la ho rala | 1200m/motsotso |

| 9. Tekanyo ea seporo | 3900-4600mm |

| 10. Tsela ea ho khanna | Taolo ea lebelo la phetoho ea maqhubu a hona joale a feto-fetohang, drive ea likarolo. |

| 11. Mofuta oa sebopeho | Mochini o ka letsohong le letšehali kapa le letona. |

Boemo ba Tekheniki ba Ts'ebetso

Makhasi a patsi le makumane a masoeu →Sistimi ea ho lokisa setoko →Lebokose la hlooho →Karolo ea ho etsa terata →Karolo ea ho omisa →Karolo ea ho thekesela

Mokhoa oa ho Etsa Pampiri

Litlhoko tsa Metsi, motlakase, mouoane, moea o hatelletsoeng le setlolo:

1. Metsi a hloekileng le boemo ba tšebeliso ea metsi bo sebelisitsoeng hape:

Boemo ba metsi a hloekileng: bo hloekileng, ha bo na 'mala, lehlabathe le tlaase

Khatello ea metsi a hloekileng e sebelisoang bakeng sa boiler le sistimi ea ho hloekisa: 3Mpa, 2Mpa, 0.4Mpa (mefuta e 3) Boleng ba PH: 6~8

Boemo ba ho sebelisa metsi hape:

COD≦600 BOD≦240 SS≦80 ℃20-38 PH6-8

2. Paramethara ea phepelo ea motlakase

Motlakase: 380/220V ± 10%

Motlakase oa tsamaiso ea ho laola: 220/24V

Maqhubu: 50HZ ± 2

3. Ho sebetsa ka mouoane khatello bakeng sa dryer ≦0.5Mpa

4. Moea o hatelletsoeng

● Khatello ea mohloli oa moea: 0.6 ~0.7Mpa

● Khatello ea ho sebetsa: ≤0.5Mpa

● Litlhoko: ho sefa, ho tlosa mafura, ho tlosa metsi, ho omisa

Mocheso oa phepelo ea moea: ≤35℃

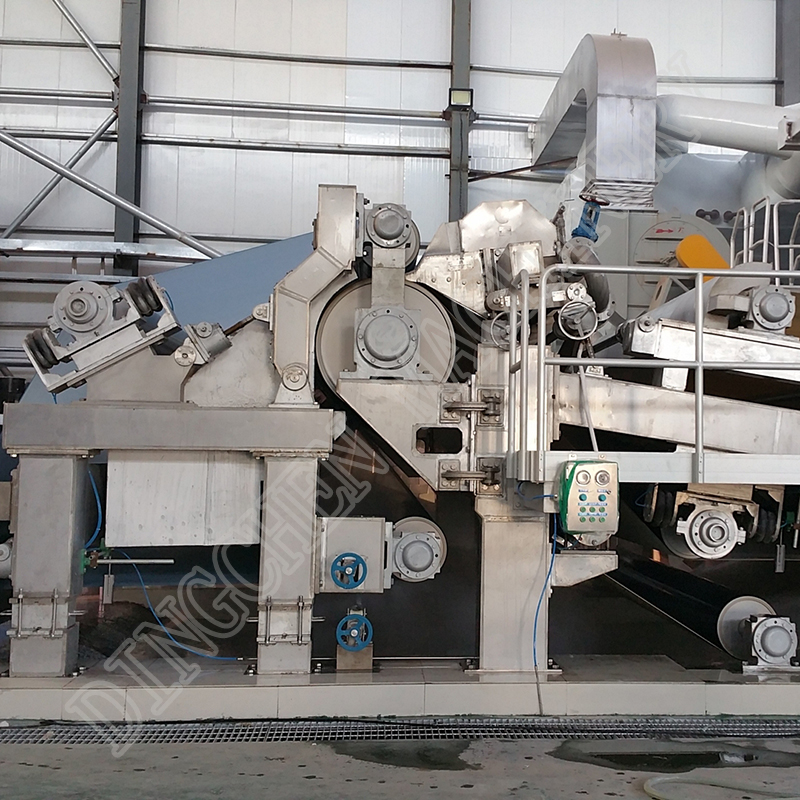

Litšoantšo tsa Sehlahisoa